Product Catalogue

- Pneumatic Air Nailers

- Pneumatic Air Staplers

- Cordless Nailers & Staplers

- Industrial Collated Nails

- Industrial Collated Staples

- Specialised Fastening Tools

- Specialised Fastenings

- Air Compressors

- Pneumatic Components

- Cordless and Pneumatic Accessories

- Rebar Accessories

- Rebar Tools

- Rebar Tying Wires

- Rebar

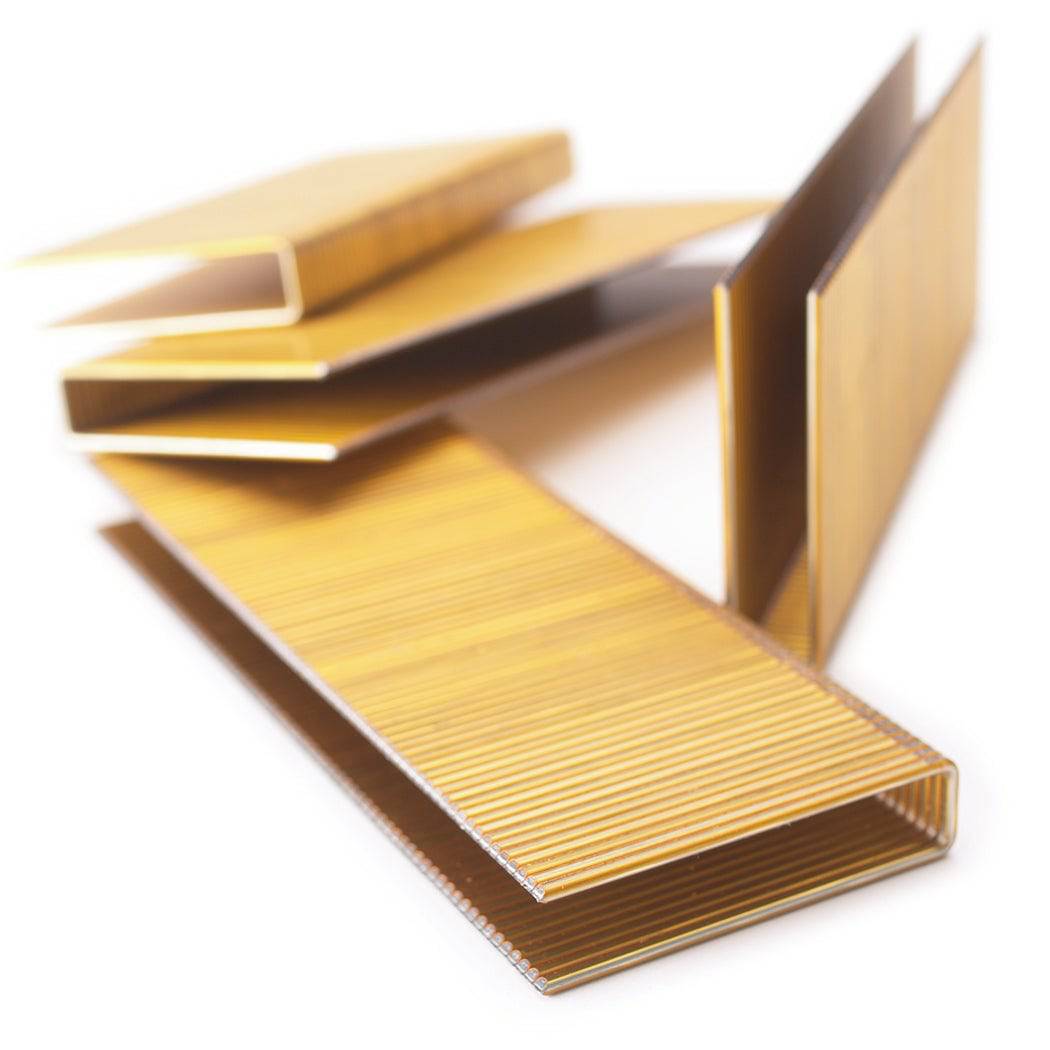

Industrial Collated Staples

51 products

Showing 1 - 24 of 51 products

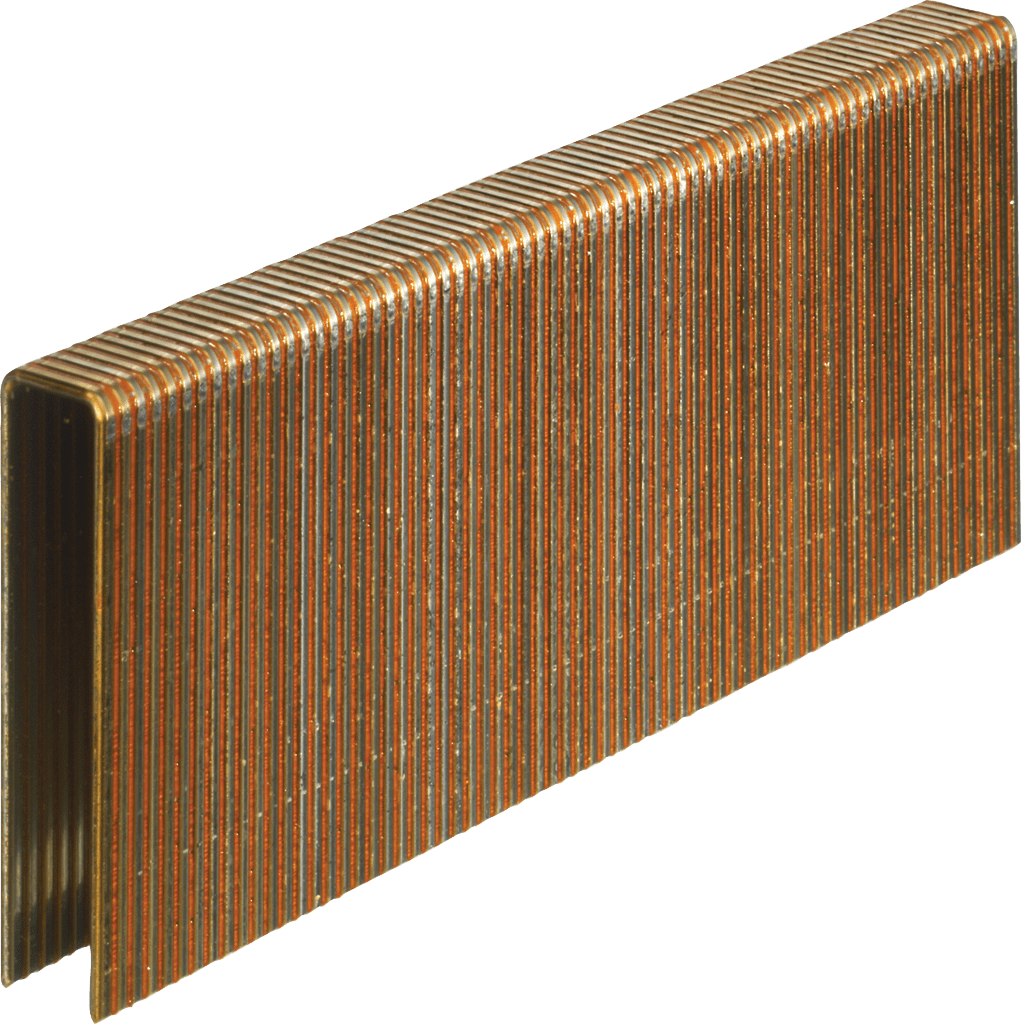

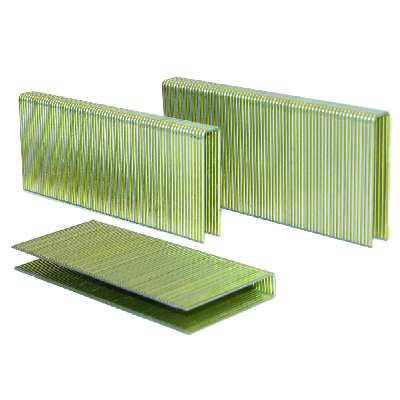

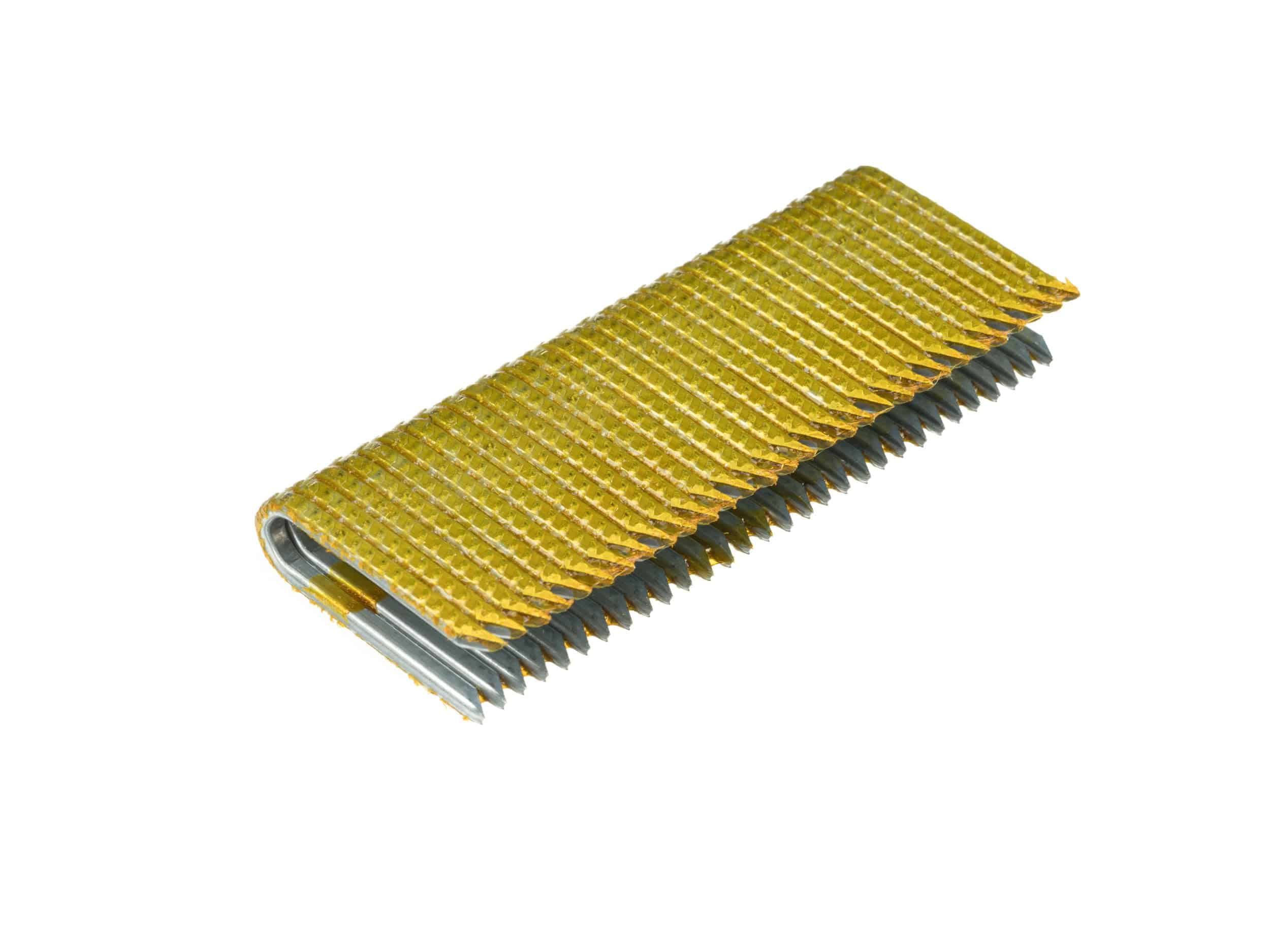

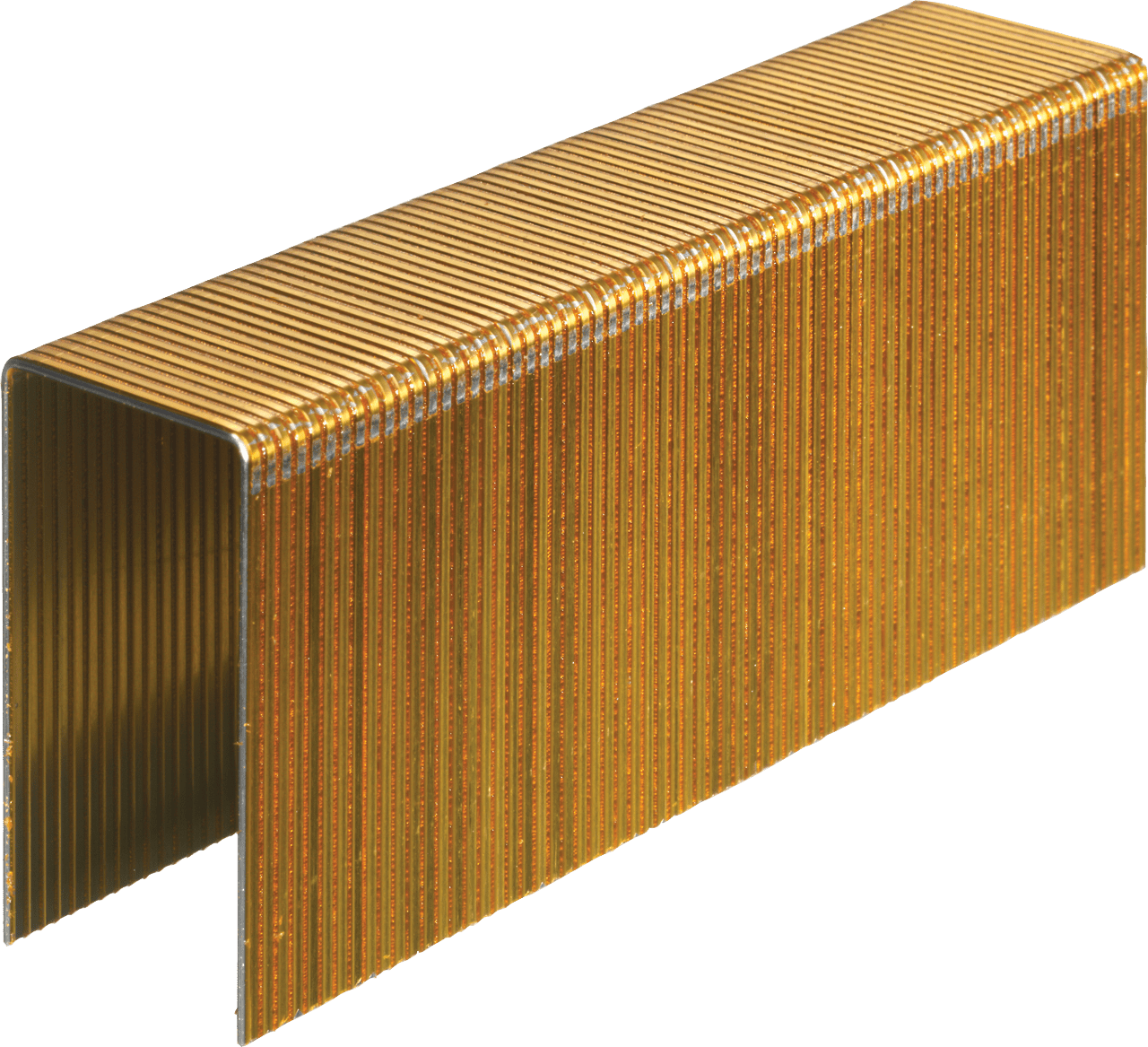

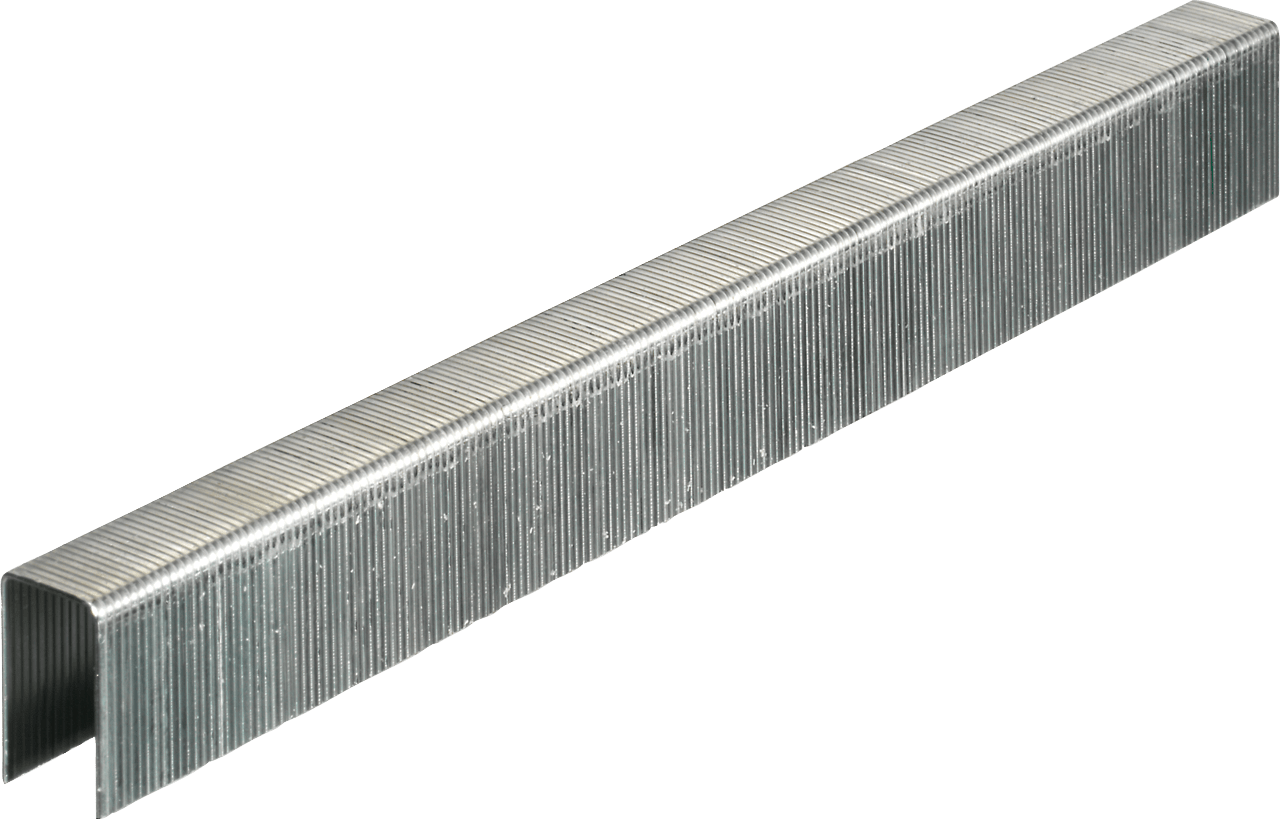

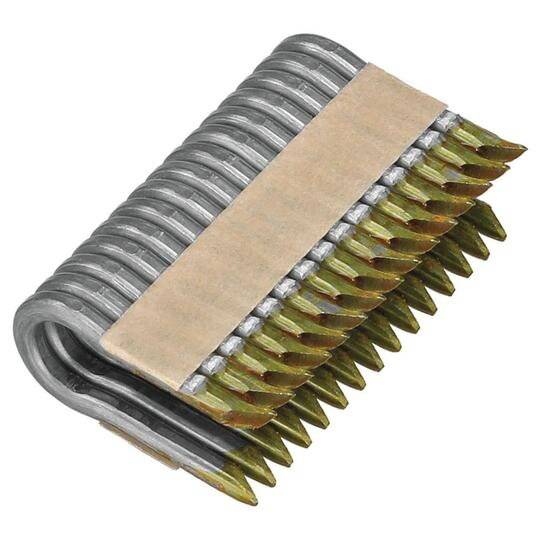

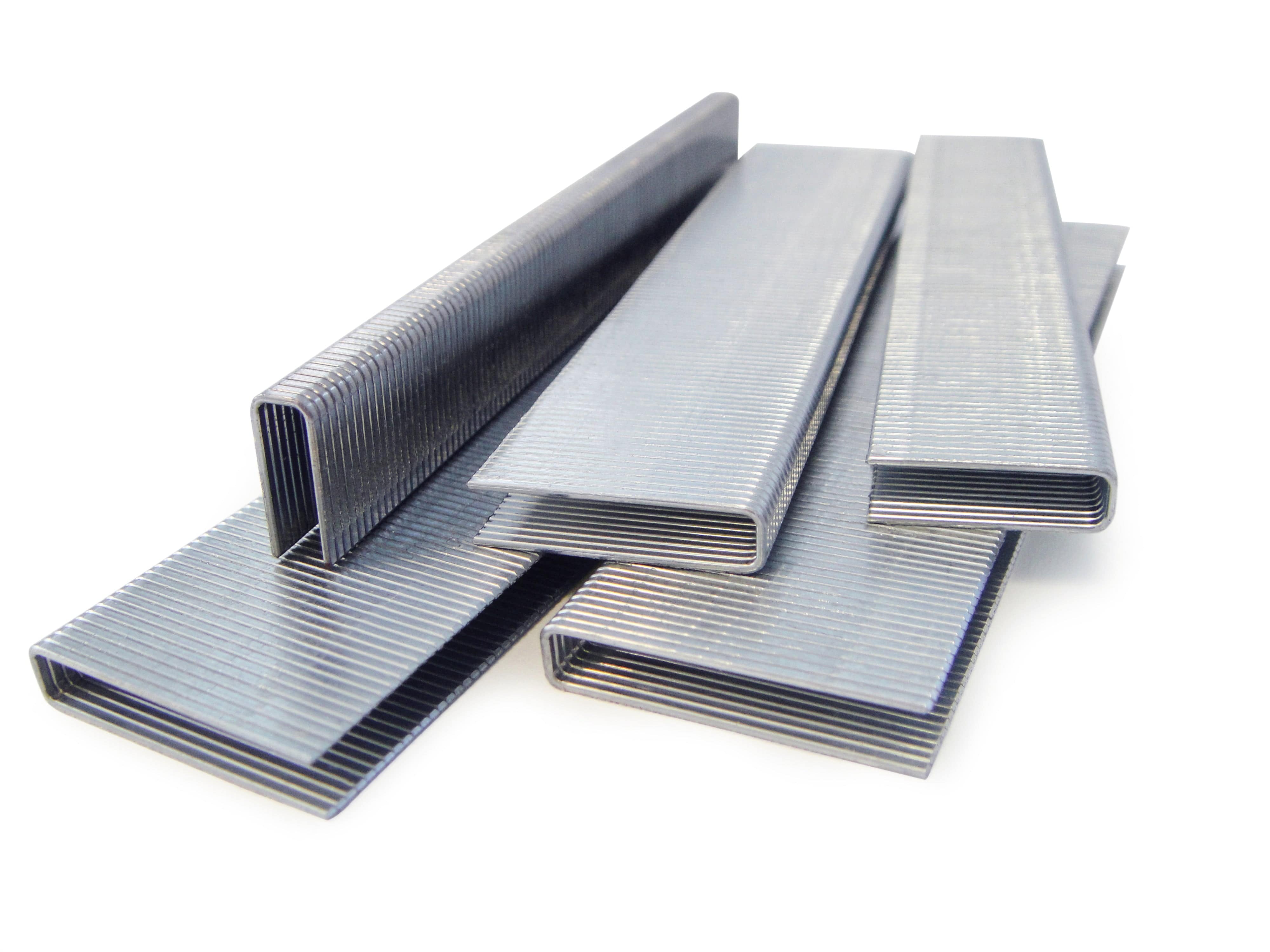

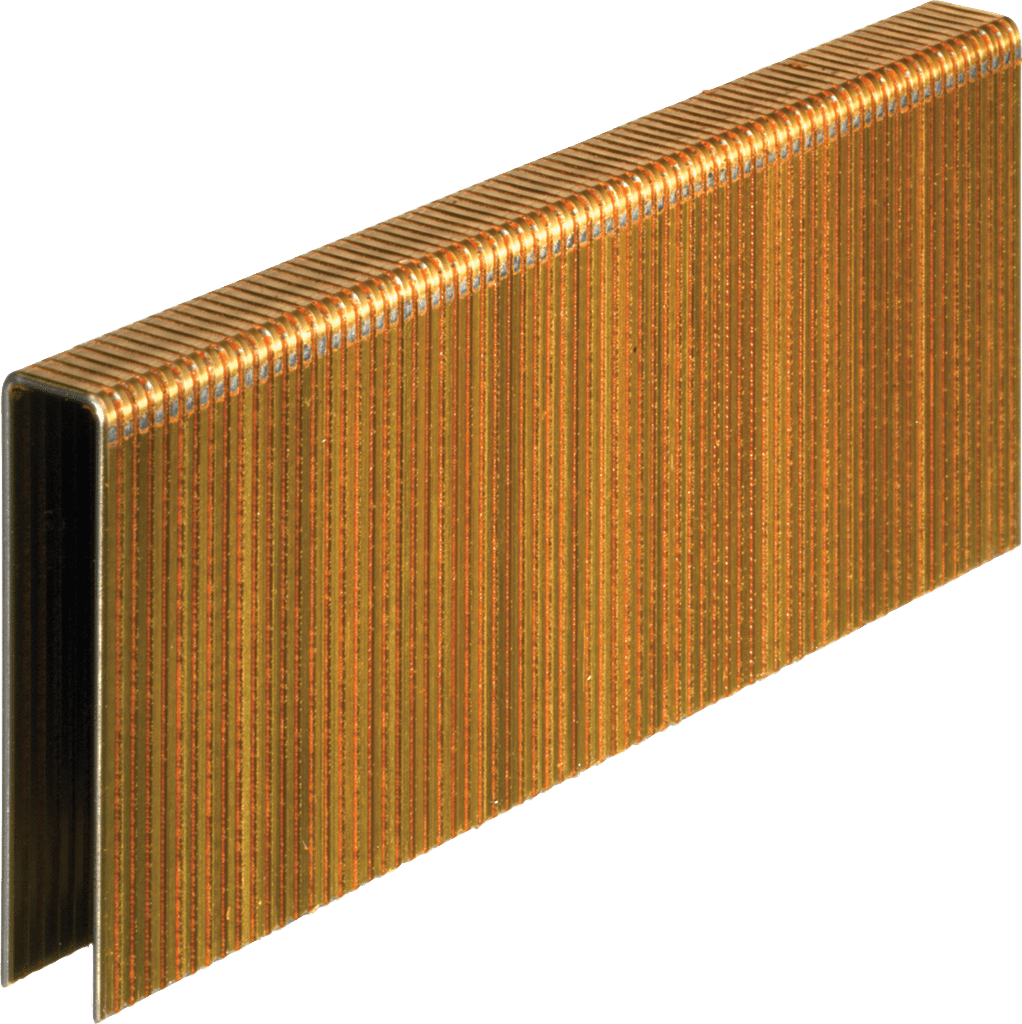

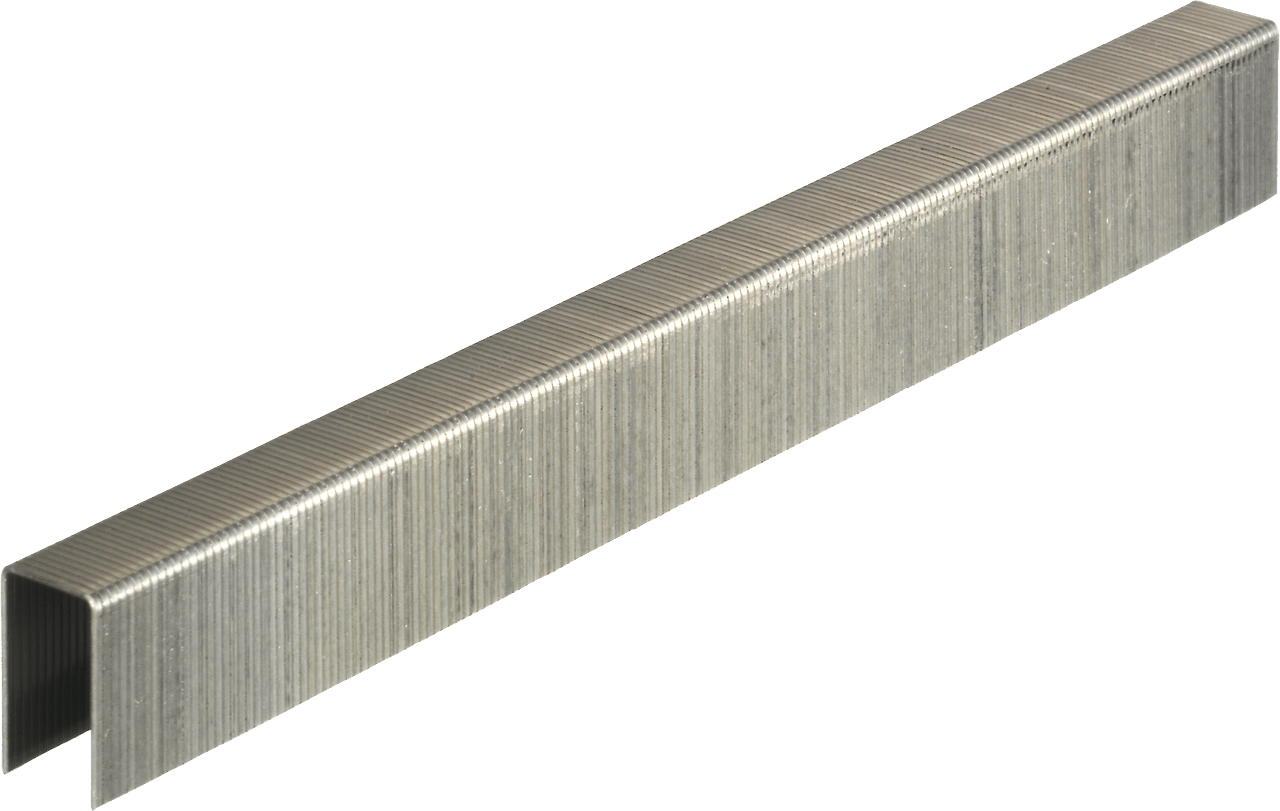

Designed to fasten a variety of materials together, our range of galvanised staples, stainless steel staples, bright staples, bezinal staples and copper staples are produced in lengths as short as 4mm and as long as 130mm. Our industrial collated staples include both framing staples and upholstery staples in type 1, type 14, type 32, type 50, type T50, type 71, type 80, type 90, type 92, type 97 type A, type B, type E, type F, type G, type J, type K, type L, type M, type N, type O, type P, type Q, type S, type SP and type U variations. A staples “type” is determined by its crown and wire thickness (gauge). Our comprehensive range includes narrow crown staples, medium crown staples and wide crown staples, as well as fine wire staples, medium wire staples and heavy wire staples, providing you with an abundance of options, allowing you to undertake a variety of stapling applications. We also supply fencing staples for fencing and wiring applications and carton closing staples for packaging.

Industrial Collated Staples

Designed to be used with a pneumatic, or cordless stapler, industrial collated staples are available in a wide variety of shapes, sizes, finishes, lengths and thicknesses, all for use in different applications, environments and weather conditions. The most common finishes are galvanised staples and stainless steel staples, while other less common finishes include copper staples and bezinal staples.

Staple’s “Type”:

As there are so many different variations of staples, it can be tricky to identify what staple to use with which stapler. Fortunately, almost all staples have a “type”, this “type” helps match the correct staple with the correct stapler. For example, type 71 staples are designed for use with type 71 staplers. Staples are given their “type” based on two main factors, the thickness of their wire and the width of their crown. These two factors, along with a staple’s finish, are the main distinguishing factors between different staples. Some common examples include Type 97 staples, Type 92 staples, Type 90 staples, Type 80 staples, Type 71 staples, Type T50 staples, Type 50 staples, Type 32 staples and Type 14 staples. However, as mentioned above, not all staples follow this pattern and an example of this is fencing staples, which don’t have a numerical “type”.

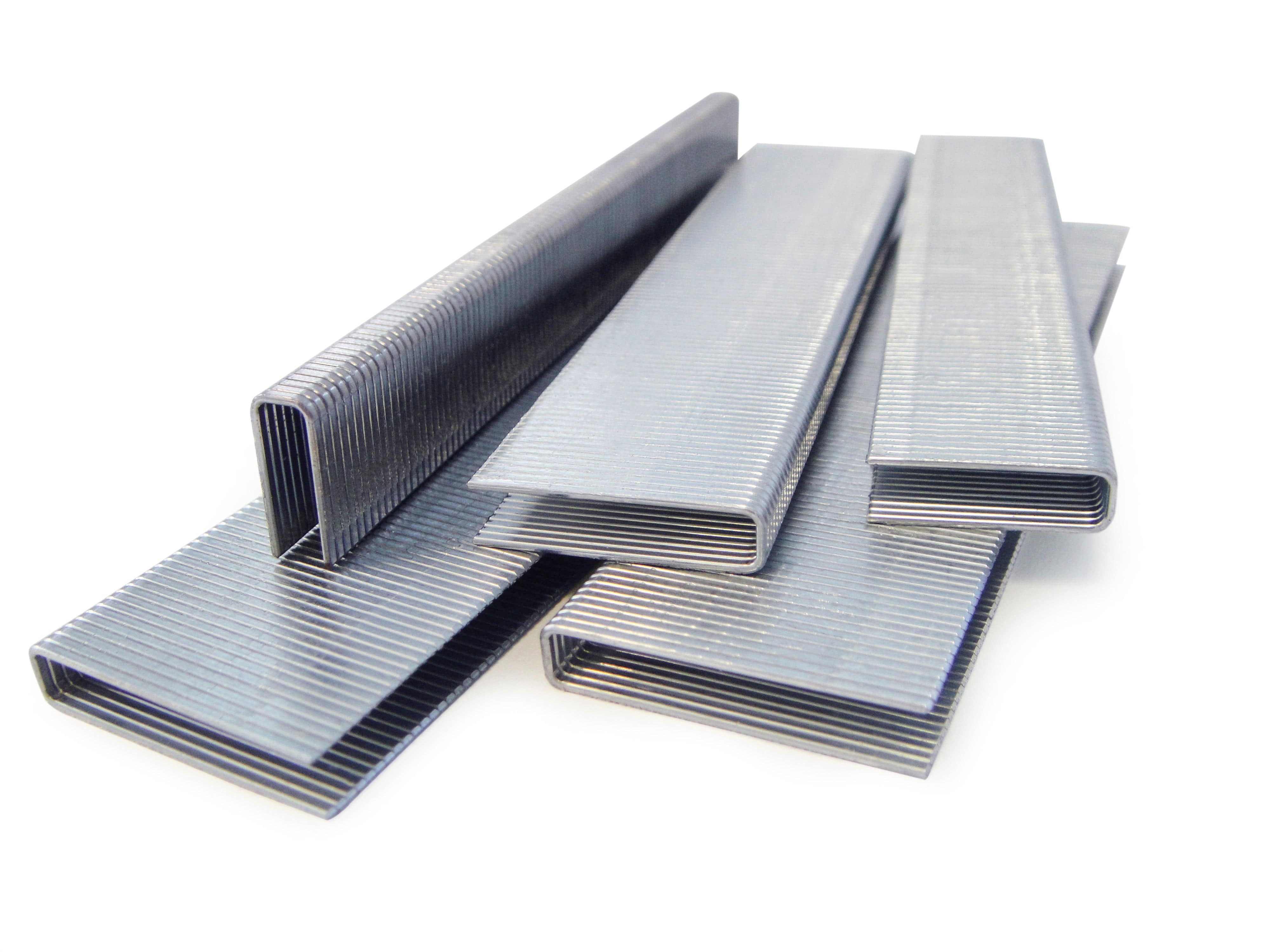

Staple’s “Crown”:

The bridge that connects the two legs of a staple together, a staple’s crown refers to its width. It is the part that is visible once stapled. There are three main groupings:

- Narrow Crown Staples – Virtually unnoticeable once fired, they are the narrowest type of staple and are designed for applications where only a small area needs to be covered. They therefore provide the most aesthetic finish.

- Medium Crown Staples – A middle ground option between narrow crown and wide crown staples. They are an ideal option in applications where a reasonable amount of space needs to be covered, but where the aesthetic finish is also important.

- Wide Crown Staples – The widest of all staples, they are designed for applications that require a large area to be covered and where the aesthetic finish is not considered a priority.

Staple’s “Gauge”:

A staple’s gauge is the thickness of its wire. The larger the gauge, numerically, the thinner the wire of the staple. For example, a 21 gauge staple is thinner than a 20 gauge staple.

- Fine Wire Staples – The thinnest wire staples of the three groupings, they are designed for applications that do not require a substantial hold and instead where the aesthetic finish is the priority. They are commonly available in 22 gauge, 21 gauge and 20 gauge variations.

- Medium Wire Staples – Manufactured in 19 gauge and 18 gauge variations, they provide a compromise between fine wire and heavy wire staples. They provide a relatively decent level of hold, but also aren’t overly noticeable once fired.

- Heavy Wire Staples – The thickest wiring staples available, produced in 17 gauge, 16 gauge and 15 gauge variations, heavy duty staples provide a strong hold and are designed for applications where the primary objective is to strongly fasten two materials together and the aesthetic appearance is not important.