Product Catalogue

- Pneumatic Air Nailers

- Pneumatic Air Staplers

- Cordless Nailers & Staplers

- Industrial Collated Nails

- Industrial Collated Staples

- Specialised Fastening Tools

- Specialised Fastenings

- Air Compressors

- Pneumatic Components

- Cordless and Pneumatic Accessories

- Rebar Accessories

- Rebar Tools

- Rebar Tying Wires

- Rebar

Industrial Collated Nails

2 products

Showing 1 - 2 of 2 products

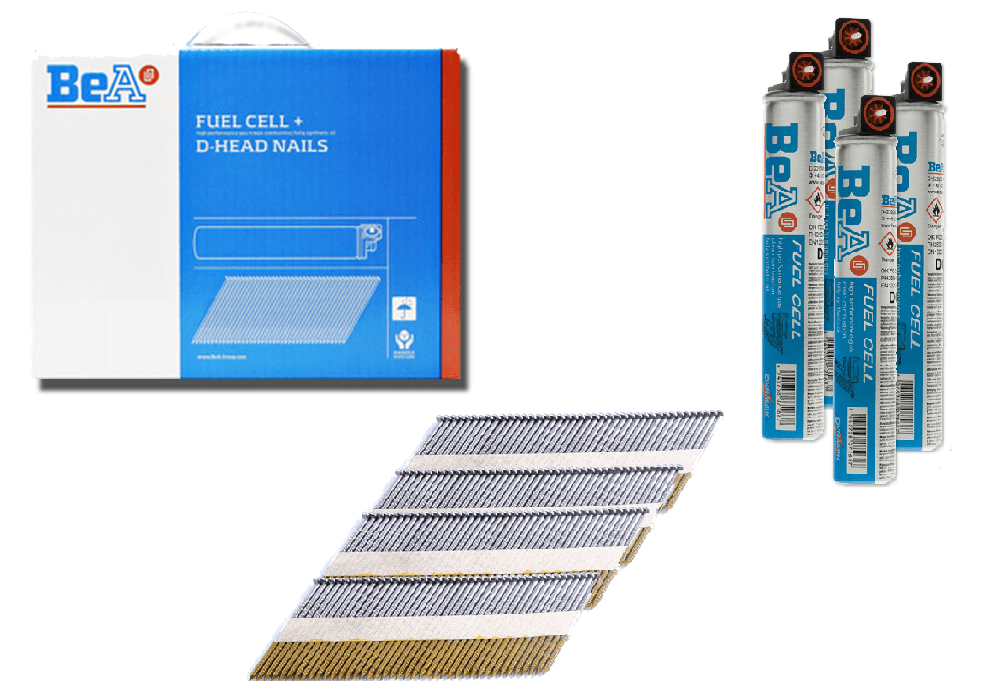

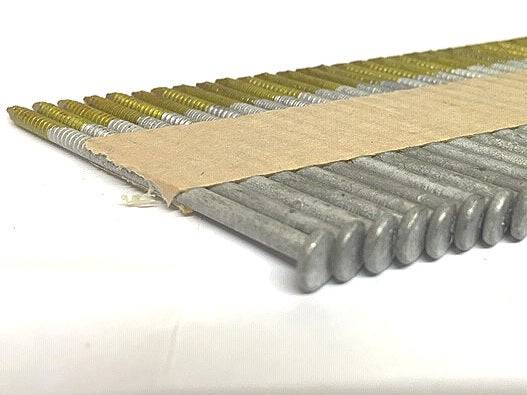

No nailer is complete without nails. We supply galvanised nails and stainless steel nails in both first fix and second fix variations. We also supply less common options such as STANOX and bright industrial collated nails. Our first fix nails, available in strips (strip nails) and coils (coil nails), are suitable for heavy duty and structural applications. They are produced in both straight and angled variations (15 degree, 16 degree, 20 degree, 21 degree & 34 degree), with either ring, smooth or screw shanks. As well as this, they are available in varying sizes, with diameters ranging from 1.6mm-3.8mm and lengths ranging from 15mm-130mm. Our second fix nails, for finish and trim applications, include 23 gauge, 21 gauge, 18 gauge, 16 gauge & 15 gauge, finish nails, brad nails and headless pins. They are available in both straight nail and angled nail variations (20 degree, 26 degree & 34 degree), in lengths from 10mm-65mm. We also supply specialised nails such as T nails, L cleats, T cleats & SCRAILS.

Industrial Collated Nails

Industrial collated nails are manufactured in two main finishes, galvanised and stainless steel, for use in a number of environments and weather conditions. Other common finishes include STANOX and bright. As well as this, nails are produced in both angled and straight variations. In general, nails can be categorised into two main groups, first fix and second fix. Whether nails are first fix or second fix depends largely on the type of applications they can be used for.

First Fix Nails:

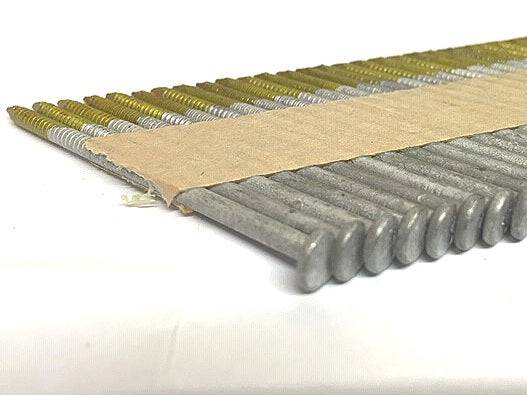

Designed for heavy duty and structural applications, first fix nails are collated in two main ways, as strip nails and coil nails. There are three main parts to a first fix nail, these are its head, shank and point. These will affect the type of environments and applications it can be used for.

- Head – The head of a nail is the top of the nail, the part that is visible after it has been fired. The two most common types are clipped head and full head (round head). Clipped head nails are collated closer together, however, their use is banned in some jurisdictions. Another option is offset head nails, although these are far less common.

- Shank – A nail’s shank determines the amount of hold a nail provides after being fired. Different types will provide different holds and are designed for different types of materials and environments. The most common types are smooth shank, ring shank and screw shank.

- Point – When firing a nail, the point is the first part to enter the intended target. It is important to pick a nail with the correct point, to avoid damaging and splitting the material that it enters. Chisel point, blunt point and diamond point are all common types of nail points. Less common options include cinch point and flat point.

Second Fix Nails:

Designed for use in trim and finishing applications, second fix nails can be organised into three main groups. The category they are placed into depends on the gauge of nail they represent. A nail’s gauge refers to its thickness. The smaller the gauge, numerically, the thicker the nail, the stronger hold it provides and thus the more noticeable it will be once fired.

- Finish Nails – Available in 14 gauge, 15 gauge and 16 gauge variations, finish nails provide the strongest hold out of any second fix nails, although they also leave the least aesthetic finish. Galvanised finish nails and stainless steel finish nails are both commonly available.

- Brad Nails – A middle ground option, providing a reasonable hold and a relatively aesthetic finish, 18 gauge brad nails are an extremely popular option. Whether a user requires galvanised brad nails, or stainless steel brad nails, depends on the type of environments and weather conditions they expect the nails to be exposed to.

- Pins – Headless pins provide the most aesthetic finish out of all second fix nails. They are available in both 21 gauge and 23 gauge variations and are designed for use in applications where the aesthetic finish is the priority. While galvanised pins and stainless steel pins are most common, STANOX pins are also widely available.